FPT Industrial's eBM 5 Battery Management System receives external ISO 26262 ASIL C certification from TÜV SÜD

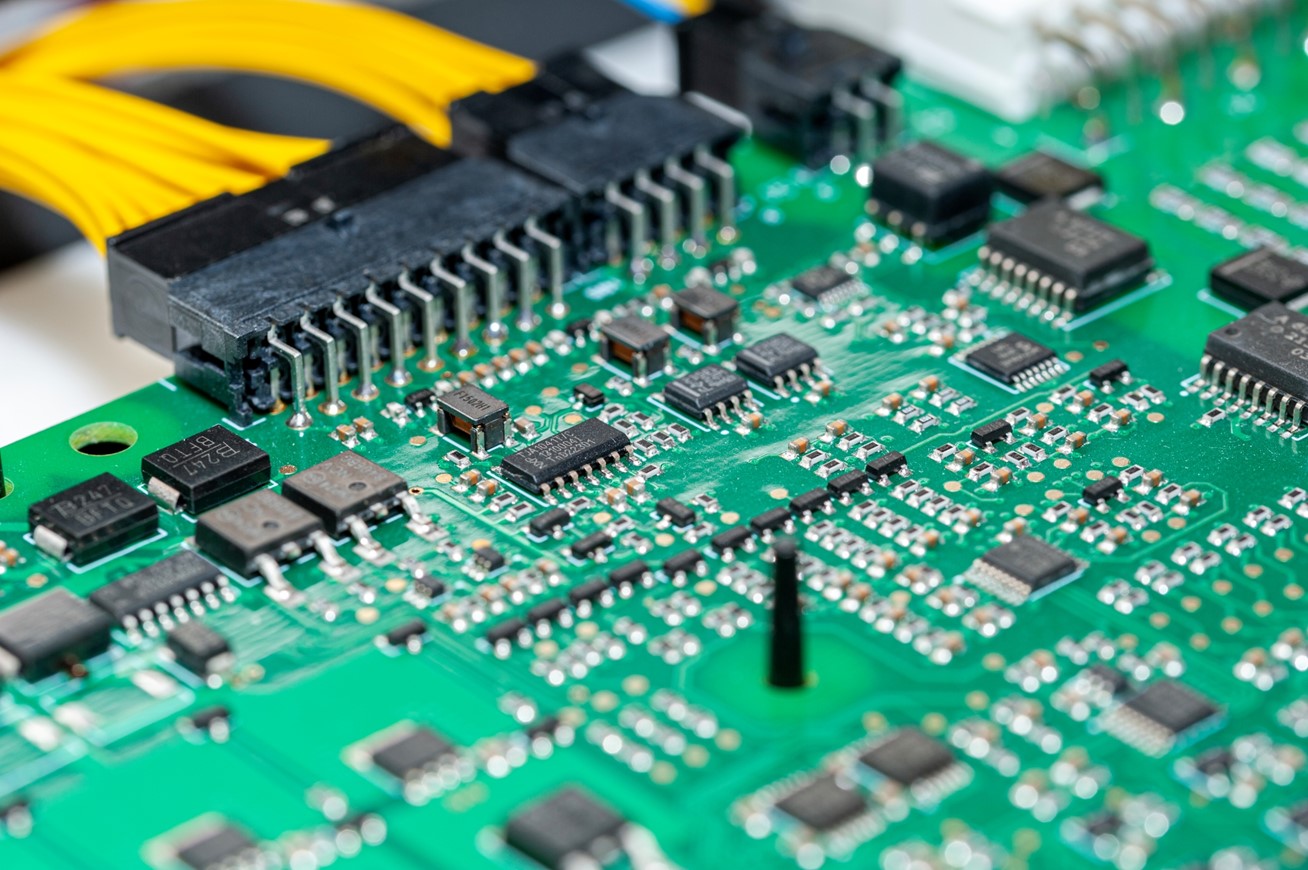

This result highlights the qualities of the fifth-generation battery management system, designed and developed entirely in-house by the integrated FPT Industrial and Potenza Technology team, from the circuitry right through to the software base and application layers. This state-of-the-art system is defined by flexibility and scalability. With a highly modular design at its core, it is compatible with 400- or 800-volt battery systems, which can be configured at an application level to optimize vehicle efficiency and performance. This enables OEMs to maximize the system’s effectiveness for each use case, right across the mobility spectrum – from commercial vehicles through to hypercars – including multi-pack management (which is not in scope of the certification) without an additional controller. The eBM 5 is currently in volume production for the IVECO eDaily MY24, as well as for numerous other customers.